The scope of application

Rotary infusion bags, tube forming high-frequency machine used in the medical industry, such as: medical infusion bags, medical blood transfusion bags, medical catheter bag, rinse bags, drainage bags and other disposable medical supplies bag containing about 10% of the PVC composition Welding, the machine can be completed a one-time welding, improve product efficiency and quality.

Features:

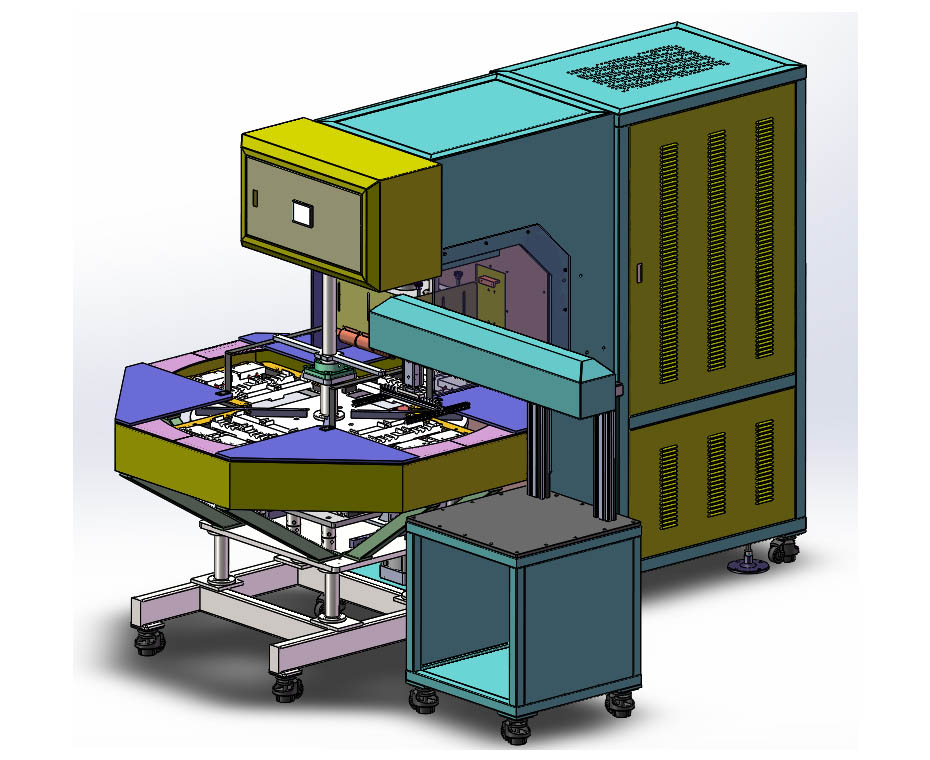

1. Rotary infusion bag, tube forming high-frequency machine, tube forming high-frequency machine for disc design, structural stability, easy adjustment of the mold level. Can complete the bag and pipe welding, the product once formed. Compared with the old mode of production to reduce labor, improve production efficiency.

2. In the production process, the operator will place the material and then automatically exit to the initial position according to the pre-set time after the material is welded. The operator takes the finished product and the above action is a complete product production cycle.

3. High-frequency current core components - oscillator, is my company to send someone to study in Germany and Germany after the independent research and development of a new generation of high stability, high-performance oscillator, is the company's unique high-quality products in the domestic technology The most stable, fast welding time, high efficiency, similar products in the domestic market at least 10% to 20%. High-frequency oscillator directly affect the stability of the device is the most important part. Many years ago the company completely separated from other colleagues in accordance with the traditional mode of manufacture of imitation oscillator.

4. Rotary infusion bag, tube forming high-frequency machine is equipped with imported high sensitivity 557 spark protection device to prevent damage to the mold; machine with high current protection device to prevent excessive current damage to the internal electronic components. Protection device is one of the key equipment is good or bad, a direct impact on the late mold usage costs and production efficiency, product quality.

5. Anti-electromagnetic shielding device: This device is equipped with a professional anti-electromagnetic shielding device to the outside world to achieve interference-free, this device is a passive device, the main preventive effect. Will produce electromagnetic wave components are mainly high-frequency oscillator, so we can see the high-frequency oscillator directly affect the stability of the equipment;

Rock Zhen equipment purchase considerations

Company

Plastic packaging machine, automatic high frequency machine, high frequency, packaging machine heat, high frequency machine, high frequency heat sealing machine, high frequency welding machine, high frequency welding machine, high frequency equipment, fusing machine

About the company

Shanghai Yan Zhen Automation Equipment Co., Ltd. was established in 2006, after more than 10 years of growth and development, the Secretary after several changes, is located in the beautiful scenery and long history of Shanghai Zhujiajiao ancient town of Qingpu District

About equipment

All equipment by our independent research and development production, the first mold proofing, until the customer satisfaction and cooperation

about the price

Equipment prices from different power, configuration, model, craft decisions, subject to negotiation, not allowed to quote

About quality

All equipment parts have been formal channels of procurement, domestic and foreign well-known brand suppliers

About Logistics

Car transport, shipping post I Division commitment (except for special circumstances)

About equipment installation conditions

Customers take delivery and installation by the buyer, before delivery, the buyer must provide gas source, 380V power supply, unloading forklift

About after sales

Equipment from the date of manufacture free of charge year warranty and lifetime maintenance, parts warranty damage or failure to repair equipment failure, the company only charge parts costs and on-site service fee, in the shortest possible time to provide solutions and on-site service

About installation and debugging

Equipment sent by the demand side prior to shipment to the factory inspection, acceptance and sent to the need to plant, Division I will arrange professionals on-site guidance

About delivery time

Standard machines are available from stock, non-standard custom negotiators need to negotiate, delivery time to be required to pay the deposit after the deposit

Contact information

18964959113Īó13611901916