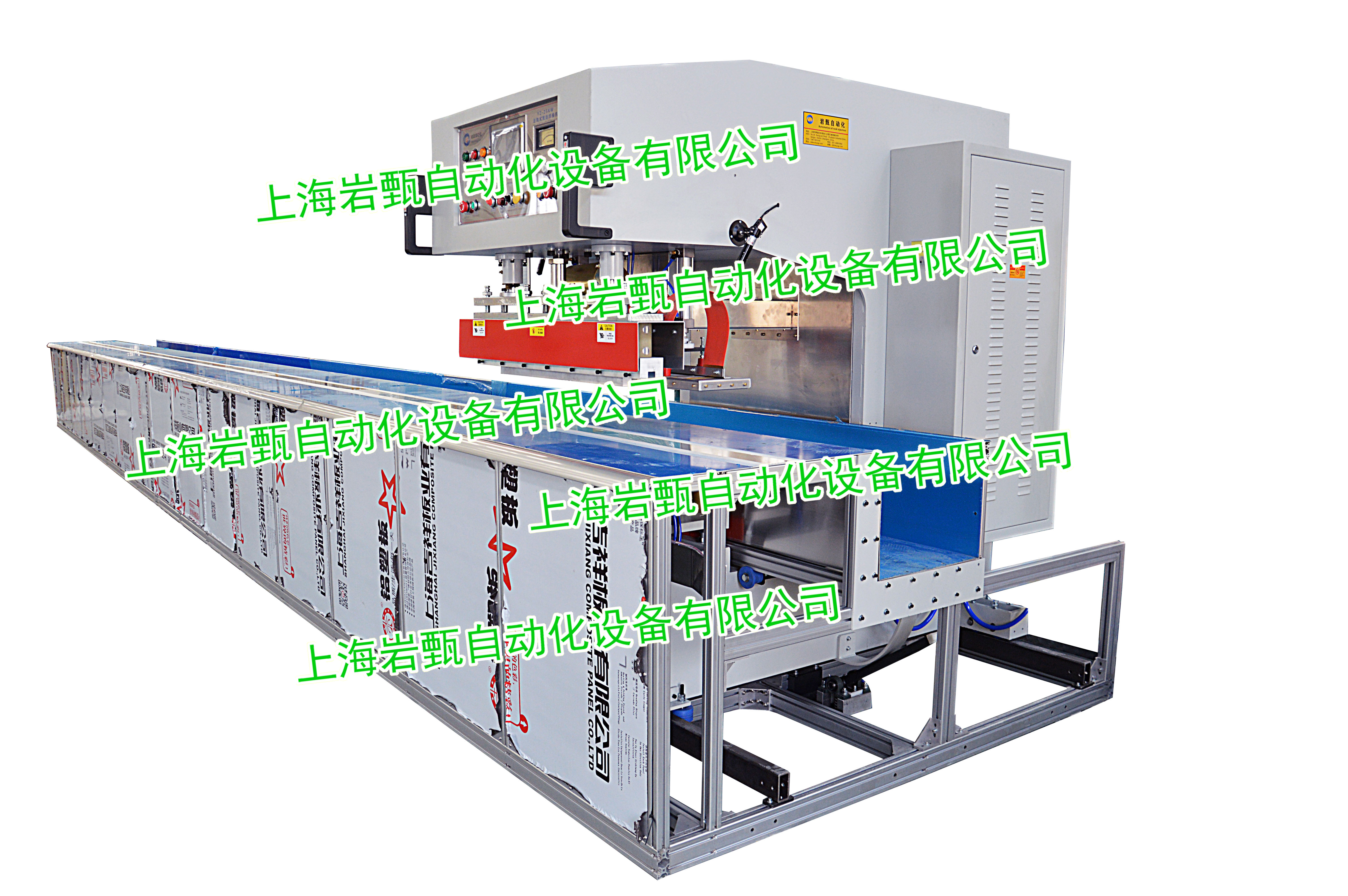

Scope of application: Mobile machine head, user-friendly operating system, suitable for large-scale tensioned membrane construction projects such as gas film halls, training halls, coal storage grids, sports halls, exhibition halls, etc. The length of the mobile desktop can also be customized according to specific customer requirements.

Equipment features:

1. PLC automation computer control, fully servo motor drive, automatic movement, automatic welding, parameter automation can be adjusted. All process actions, currents, and movement data adopt independent logic algorithms, reaching the international level of intelligent digital control. The operation is divided into four modes: trial mold, manual, semi-automatic, and fully automatic, which can meet the process operation needs of different working conditions. The equipment buttons adopt a handheld handle design, which is safe and convenient. The stacking trough adopts a strong and movable double support rod design to ensure high load-bearing capacity and long service life of the trough.

2. Equipment power: There are mainly three types: 15KW/25KW/35KW, and the length is produced according to customer needs. The track is made of reinforced European standard aluminum assembly, and the length of the track can be selected according to customer needs. The minimum order length is 6 meters, and each additional section is 6 meters. Easy disassembly and easy maintenance. Generally, a track with a length of 30 meters is equipped with a nose.